通过标签搜索: ring

Forged Heat-resisting Superalloy Disks Gear Ring

We can produce large forging,casting and welding gears according to customer's drawings.According to the working conditions and clients' request,we also can do gear grinding,surface hardening,cemented and quenching,Nitriding and quenching,etc.

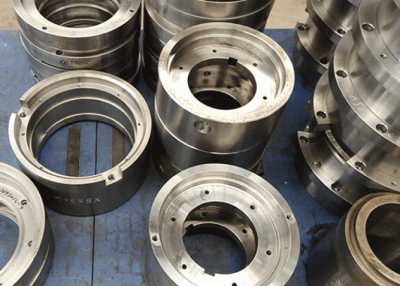

Custom High Quality Ring Forgings for Mining Machinery

The purpose of the quality analysis of ring forgings is to find out the product quality problems, find out the quality reasons, take corresponding measures to make the ring forgings that meet the technical standards, so as to meet the customer's product…

China OEM Ring Forgings for Mining Machinery

Some key problems in the integrated process of ring forgings are to determine the main factors affecting the performance of ring forgings and to analyze the compatibility between process variables. Superposition of ring forging process characteristics,…

Metal Ring Mesh Curtains

Metal Ring Mesh, Also Referred To As Ring Mesh Curtain Or Decorative Ring Mesh Metal Ring Mesh, also referred to as Ring Mesh Curtain or Decorative Ring Mesh, is a distinctive and versatile architectural wire mesh made from interlinked metal rings. Known…

304 Ring Shank Steel Common Nails

Cnow supplies carbon steel ring shank nails and stainless steel nails with ring shanks instead of smooth shanks. It is mainly used in construction and other industries.